Jewellery Laser Engraving Machine: The last word Shopping for Guide

페이지 정보

작성자 Fredrick Troede… 작성일24-11-06 15:19 조회519회 댓글0건관련링크

본문

As a result of wavelength of this laser (infrared mild), it is capable of engraving and marking all metallic jewellery, comparable to gold, silver, and platinum. Moreover, it may laser engrave plastic. With its max. engraving velocity of four,000mm/s and handheld design, f1 excels at on-site engraving projects. The most typical and affordable choice for jewellery engraving is a diode laser engraver. These Lasers utilize crystals to create beams. They supply high output power and vitality effectivity, making them suitable for reducing, welding, and engraving materials corresponding to metals, ceramics, and plastics. Additionally, crystal lasers can operate at different wavelengths, permitting for precise control over the laser beam’s characteristics and absorption properties in the material being processed.

Certain metals or finishes can reflect the laser light, lowering efficiency or necessitating changes to the process. Read the merchandise' technical descriptions to learn concerning the applicable supplies for each laser mannequin. In instances of excessive corrosion the place the fabric integrity is compromised, laser rust removing won't be suitable or would possibly require preliminary therapy to ensure the laser can successfully remove the rust without damaging the fabric. Refraction causes the laser to shoot downward toward the focusing lens, which then focuses the laser to form a really nice spot. The adjustment strategy of the mirror bracket: the mirror and the laser are at a 45-degree angle, which makes it troublesome to evaluate the laser level. It is essential to 3D print a forty five-diploma bracket for auxiliary adjustment, paste the textured paper on the by hole, and the laser is turned on. Spot shooting mode (on time zero.1S, power 20% to prevent penetration), modify the height, place and rotation angle of the bracket, in order that the sunshine spot is managed in the middle of the spherical hole. The technique of adjusting the angle of the first floor mirror: transfer the Y-axis near the mirror, laser dot, then move the end of the Y-axis away, and dot again.

The identical laser might be very dangerous if it comes involved with the human physique. Subsequently, it is best to always select a laser engraver with most security options like an acrylic laser container, safety goggles, emergency button, Lid sensor, and G-sensor. Laser Engraver for Metal vs. Wood is comparatively softer than metal and rapidly vaporizes with a suitable laser engraver. On the contrary, metal is a hard materials that requires one of the best fiber laser engraver for optimum engraving. Laser engravers for wood have a strong CO2 laser. If you wish to convey knowledgeable end result or run a enterprise, then it is better to choose a excessive-budget machine with nice quality. Whereas novices or hobbyists can select laser cutters at low prices. Velocity and high quality are important elements, particularly for individuals working a business. Depending on a machine that has the adequate pace to complete your activity at any given time is vital. The xTool P2 is our high decide for one of the best laser cutter. It is not the most affordable laser cutter around, however with a number of superb equipment, unbelievable software and a cutting size and velocity which are exhausting to ignore, it takes the crown from the Glowforge Pro, however simply barely. It's large, so ensure you have room in your workshop to home it.

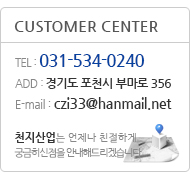

Some manufacturers additionally supply free samples to get you started. All the time belief them first earlier than taking risks! You may also ask customer support if there are not sure issues. That’s why responsive customer service is also an important consideration. Before you officially begin, https://realthouse.com/neobhodimoe-rukovodstvo-po-lazernym-stankam-po-metallu-s-chpu/ check if the assembly is done properly. Ensure that the interlocks, elements, screws, and switches are in place. Tall Column Design: This distinctive function accommodates simple integration into manufacturing lines, permitting for seamless operations. Built-in Touch Display: The contact display, armed with intuitive marking software program, simplifies the marking process, enabling operators to shortly enter or modify marking data. Targeted Performance: Designed primarily for marking easier content like dates, serial numbers, and different identifiers.

댓글목록

등록된 댓글이 없습니다.